My Latest Ball Mill Design YouTube

Jan 12, 2018· Please subscribe! Thank you for watching! I designed this ball mill entirely for ease of maintenance. It uses Polyurethane Skate wheels and 608ZZ bearings. It has a laptop power supply and a basic ...

WhatsApp)

WhatsApp)

Jan 12, 2018· Please subscribe! Thank you for watching! I designed this ball mill entirely for ease of maintenance. It uses Polyurethane Skate wheels and 608ZZ bearings. It has a laptop power supply and a basic ...

Feb 18, 2019· Dec 04, 2012ball mill foundation design. Home ball mill foundation design. sbm company is a research and development, production, For the foundation design and . ball mills foundations design ...

Dec 12, 2016· The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific ...

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter (Figure ).The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

The ball mill is a tumbling mill that uses steel balls as the grinding media. .. of hard agglomerates which can result when liquids are removed from powder. Contact US Ball Mill Maintenance Installation Procedure 911 Metallurgist. May 30, 2017 . Ball Mill Lubrication .

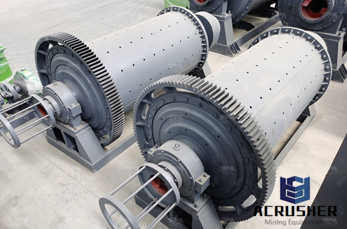

Ball mills Ball mills are used for dry and wet grinding of different materials such as cement materials, cement, lime, and ceramic materials. PSP Engineering has continuously refi ned the design of its ball mills. Horizontal ball mills have become a reliable part of grinding plants Main characteristics of ball mills seated on shoetype bearings

All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material. Grinding can be undertaken in many ways. The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder or drum.

Jun 20, 2015· The effect of Ball Mill RPM speed going from subcritical to supercritical helps understand the Ball Mill Working Principles of ballonball VS ballonshell grinding. The Motion of the Ball Charge

Horizontal Ball Mills. Horizontal ball mills are the most common type. The basic design is the same but the details can vary slightly. A drum, which is usually detachable, has a door that can be used to load in the material to be processed.

Ball Milling An efficient and ecologically friendly synthetic approach ‐‐‐ Jackie Ding

Ball Mills Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800''s. The basic construction of a ball mill is a cylindrical container with journals at its axis.

The optimal ball diameter in a mill 333 The grinding efficiency of the narrow particle size fractions with ball charge of various diameters has been observed through the constant of milling rate k in the equation of the grinding kinetics law for the first order grinding R=R 0

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

Design Method of Ball Mill by Discrete Element Method The grinding rate of gibbsite in tumbling and rocking ball mills using fins was well correlated with the specific impact energy of the balls calculated from Discrete Element Method simulation.

Nov 10, 2017· More Details : ball mill design calculation software free Ballmill Design Power Draw EduMine Online Tool. DETALS ABOUT BALL MILL SIZING AND DESIGN : ball mill design .

Figure 5. High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc. liner design and material of construction are integral and cannot be chosen in isolation.

Several types of ball mill exist. They differ to an extent in their operating principle. They also differ in their maximum capacity of the milling vessel, ranging from litres for planetary ball mill, mixer mill or vibration ball mill to several 100 litres for horizontal rolling ball mills.

PDF | This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would ...

Manufacturer of balls includes ball mill balls. Specifications of ball mills include 12 in. x 12 in. cast iron drum size, 285 ball charge, one to two phase, 110 to 440 V voltage, cycles in the range of fifty to sixty lbs. iron ball charge weight. Ball mills are available with iron stands, receiving hand screen pans digital counters.

some of the key design criteria for making your own ball mill. This is a good starting point for anyone interested in making their own black powder, which is the foundation upon which all other pyrotechnics have been built. Grinding Theory: There are a lot of misconceptions about what goes on in a ball mill.

Ball mills: design and operating principle. The Samara Strommashina plant has been manufacturing ball mills since the middle of the twentieth century. Hundreds of mills of most diverse modifications have been manufactured over 70 years of the plant operation.

Ball mills designed for long life and minimum maintenance overflow ball mill sizes range from 5 ft. x 8 ft. with 75 HP to 30'' x 41'' . and as much as 30,000 HP. Larger ball mills are available with dual pinion or ring motor drives. Our mills incorporate many of the qualities which have made the Marcy name famous since 1913.

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls .

Ball Mill Design. A survey of Australian processing plants revealed a maximum ball mill diameter of meters and length of meters (Morrell, 1996). Autogenous mills range up to 12 meters in diameter. The lengthtodiameter ratios in the previous table are for normal applications.

WhatsApp)

WhatsApp)