Brochures Flyers for Download RETSCH

On our download page you will find all available RETSCH brochures and flyers ready for download. Click here to get to the overview.

WhatsApp)

WhatsApp)

On our download page you will find all available RETSCH brochures and flyers ready for download. Click here to get to the overview.

Dec 25, 2019· Download ball mill design Comments. Report "ball mill design" Please fill this form, we will try to respond as soon as possible. Your name. Email. Reason. Description. Submit Close. Share Embed "ball mill design" Please copy and paste this embed .

· and the calculation for a ball end mill, a ball end mill parametric design system is built by development technology with CATIA 3D modeling software and Visual Basic. With this system obtaining the model of the ball end mill, the simulation is processed in Third Wave AdvantEdge software. The main contents of this paper are: 1.

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

The Ball Mill System (BMS) is a strongly coupled MIMO system,in order to implement a longterm automatic operation of the BMS effectively,and improve the automation level and efficiency, the paper present the overall design of the system,the control system is composed of Siemens SIMATIC S7400PLCS7200PLC,the PROFIBUS DP protocol and MPI protocol are both employed to setup a .

Ball mill 2000x4000. The ComputerAided Design ("CAD") files and all associated content posted to this website are created, uploaded, managed and owned by third party users.

These mills are of a special design and described on special request by all Ball Mill Manufacturers. Types of Grinding Mill Manufactured The different types of grinding mills are based on the different types of tumbling media that can be used: steel rods (rod mills), steel balls (ball mills), and rock material (autogenous mills, pebble mills).

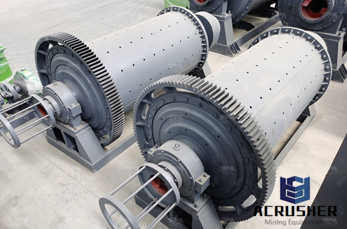

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls.

Our combined experience in ball mill design and process equipment development totals more than 60 years and allows us to put a unique spin on steel and lined mills. Ball Mill Drive Options. At Orbis Machinery we offer a variety of drive options to suit your needs: Standard shaft mount reducer and belt drive; Gearwheel and pinion

The ComputerAided Design ("CAD") files and all associated content posted to this website are created, uploaded, managed and owned by third party users. Each CAD and any associated text, image or data is in no way sponsored by or affiliated with any company, organization or realworld item, product, or good it may purport to portray.

Jul 20, 2019· A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50% of the mill volume and its size depends on the feed and mill size.

Make a Ball Mill in 5 Minutes: This is for all the pyro nuts that I came across on Instructables. This can be used to grind chemicals to a very fine grain or to polish says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use i...

Design Method of Ball Mill by Discrete Element Method collected. The diameter of the gibbsite powder was measured using a Master Sizer 2000 (Sysmex Corporation). Details of the experimental conditions are given in Table 2. Results and Discussion 1. Effects of Fins on Ball Motion in the Mill To predict ball mill grinding behavior using the dis

Ball mill design software download we are a professional mechanical equipment manufacturer, we provide original parts, service solutions, extensive training and extensive wear, crushing chambers and screening media solutions to reduce operating costs, im. View All; Ball mill jiang shu.

Ball Mill Design Pdf Download. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would rotate the ...

Ball Mill Design Software Download. Design And Simulation For Ball Mill Load Control Based Download citation on researchgate design and simulation for ball mill load control based on weighted fuzzy control algorithm due to the bad performance of ball mill load control by grinding Chat Online A .

FreeMILL, as the name indicates, is a free milling module for programming CNC mills routers. FreeMILL running inside the Alibre Design modeling software, gives you a great entry level milling software product that is completely free of cost!

Jan 12, 2018· Please subscribe! Thank you for watching! I designed this ball mill entirely for ease of maintenance. It uses Polyurethane Skate wheels and 608ZZ bearings. It has a laptop power supply and a basic ...

Figure 5. High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc. liner design and material of construction are integral and cannot be chosen in isolation.

Ball mills are simple in design, consisting of horizontal slow rotating vessels half filled with grinding media of ¼" to ". The particles to be milled are trapped between the grinding media or balls and are reduced in size by the actions of impact and attrition.

Ball Mill Design. A survey of Australian processing plants revealed a maximum ball mill diameter of meters and length of meters (Morrell, 1996). Autogenous mills range up to 12 meters in diameter. The lengthtodiameter ratios in the previous table are for normal applications.

The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects. These ball mills are also suitable for mechano chemistry.

ball mill design software download . DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR. using DEM software. For designing and analyzing the Roller press circuit Ball mill chute, UMS diameter, .

WhatsApp)

WhatsApp)