the main ponents of the ball mill peru

Conic Ball Mill Main Ponents. A ball mill is a type of grinder used to grind and blendfor systems with multiple componentsglass live chat rod mill iron ore main componentsskngroups rod mill iron ore .

WhatsApp)

WhatsApp)

Conic Ball Mill Main Ponents. A ball mill is a type of grinder used to grind and blendfor systems with multiple componentsglass live chat rod mill iron ore main componentsskngroups rod mill iron ore .

Chrome Balls (steel type 52100) are throughhardened and tempered steel balls designed to achieve maximum strength and quality. Ball hardness is in the 60–67 HRC range. They wear better than 440C .

Each bearing type has characteristic properties that make it more or less suitable for use in a given application. Matrix 1 gives an overview of the main bearing types (including their major features and .

Conic Ball Mill Main Ponents. A ball mill is a type of grinder used to grind and blendfor systems with multiple componentsglass live chat rod mill iron ore main componentsskngroups rod mill iron ore main componentscrusher xinhai is the leading supplier of mining machine and equipment at home and abroad providing many complete sets mineral live chat metallurgical testing

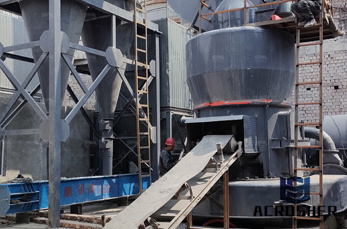

peru vanadium ore grinding mill conical energy saving ball mill for graphite in peru wet type ball mill for silica sand high efficiency compound flotation jan 26 sand ball mill processchina top quality iron ore spiralsand screwball mill .

Ball mill, a mill using balls to crush the material Bead mill a type of Mill (grinding) Burr mill or burr grinder, a mill using burrs to crush the material, usually manufactured for a single purpose such as coffee beans, dried peppercorns, coarse salt, spices, or poppy seeds

Grate Ball Mill W orking principle Grate Ball Mill is the horizontal tube rotating device, outer edge of the gear drive, two chambers, and latticetype. Moreover, according to different materials and discharging methods, there are dry ball mills and wet ball mills .

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would rotate the ...

This article on choosing milling media for a ball mill by Ned Gorski is a side article that goes with the "Ball Milling 101" Media Cautions. In his book Ball Milling Theory and Practice for the .

Comminution is very important in Peru because of the wealth of ores which A simple model of a ball mill was also available in a form which enabled a ball mill TintayaAntapaccay Expansion (Peru) Five Star Products. copper mine in southern Peru. Their first project encom passed the grouting of 6 soleplates, 1 SAG mill and 2 Ball. Mills .

The Emax is an entirely new type of ball mill for high energy input. . process optimization helped Antamina mine in Peru achieve improved mill The optimal and most. Learn More (PDF) Optimisation and Continuous Improvement of Antamina . Nov 28, 2016 . Comparison of SAG mill .

Selling Screens For Peru Mills Ball Mill iimeindiain. ball mills peru types Kbrecin small ball mill in peru As a great grinding mill for secondary crushing ball mill is an productive pulverizer View More ball mill sold to more than 20 countries manganese ore ball mill ceramic wet bal mill trade offers directory and manganese ore ball mill ...

(1) Types on the Basis of Cylinder. 1. Short Cylinder Ball Mill: The ball mill with the cylinder length (L) less than 2 times of the cylinder diameter, the ball mill with L ≤ 2D is short cylinder ball mill, which is usually of single bin structure, mainly used for rough grinding or primary grinding operation, and can realize the wide use of 23 ball mills in series.

Horizontal ball mills are the most common type. The basic design is the same but the details can vary slightly. A drum, which is usually detachable, has a door that can be used to load in the material to be processed. Sometimes like for paint mixers there will be a screen that keeps the metal balls in place. When the substance to be ...

Ball Mills How It Works Peru. ball charge but not less than 18 of the total volume. This states that AG mills are designed at 18 ball safety mills operating at maximum 12 balls get 6 ball safety while operations at maximum 18 get 3 ball .

Aug 25, 2014· The ball mill contains a hollow cylindrical shell and that will rotate about its axis. These cylinders are filled with the balls that are made up of stainless steel or rubber, to crush the material contained in it. 5. Horizontal Ball Mills. • Horizontal ball mills are the most common type in the industry. • Some horizontal ball mills have ...

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotati

Ball Mills How It Works Peru. ball charge but not less than 18 of the total volume. This states that AG mills are designed at 18 ball safety mills operating at maximum 12 balls get 6 ball safety while operations at maximum 18 get 3 ball safety.

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills .

Different Types of Ball Mills Produced A ball mill is a grinding machine popular for grinding and mixing material together into powder form. The size of metal is reduced by balls falling over the surface of metal. The machine is popular for mixing paints, ...

Ball Mills For Sale In Peru We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment milling equipment mineral processing equipment and building materials equipment Get Price Customer Case ... New and Used Ball Mills for Sale Savona Equipment is a new and used Ball ...

Working Principle Operation. The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball mills designated as 5′ x 5′ where the ...

Ball Tube Mill BHEL HYDERABAD :: Product Profile. The Ball Tube Mill is basically horizontal cylindrical tube rotating at low speed on its axis, response of over range,low air to coal ratio, ability to pulverise a wide range of coals, virtually Horizontal type .

Central transmission ball mill: The driving power of this type of mill is in the center of the fuselage, and the motor realizes the operation of the ball mill through a reducer. During operation, the hollow shaft in the center of the ball mill .

WhatsApp)

WhatsApp)