How to Grind Your Own Chicken Feed | Animals

Birds •Farm Animals •Fish •Insects •Wildlife and Exotic Animals •Reptiles, Rodents and Small Animals •House PetsHow to Grind Your Own Chicken FeedBy ...

WhatsApp)

WhatsApp)

Birds •Farm Animals •Fish •Insects •Wildlife and Exotic Animals •Reptiles, Rodents and Small Animals •House PetsHow to Grind Your Own Chicken FeedBy ...

Mar 06, 2019· #peppermill How to Disassemble, Arrange Size and Clean Wooden Pepper Grinder? AVAILABLE for grinding spices such as pepper, coriander, salt, cardamom, mustard, cumin, sumac, rice. Not available ...

A modern grinding mill must be able to deal with many tasks while providing a highdegree of grindability, with results that are fine and exact. As demands for higher performance grinding mills are continuously increasing, RETSCH is dedicated to incorporate the latest in grinding technology with ever new product developments. Product Overview

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case".

Millstones or mill stones are stones used in gristmills, for grinding wheat or other grains.. Millstones come in pairs. The base or bedstone is stationary. Above the bedstone is the turning runner stone which actually does the grinding. The runner stone spins above the stationary bedstone creating the "scissoring" or grinding action of the stones.

How To Size Grinding Mills. Media ball sizes, for example, range from about 20 mm for fine grinding to 150 mm for coarse grinding tumbling mills are typically employed in the mineral industry for primary grinding i, stage immediately after crushing, in which particles between 5 and 250 mm are reduced in size to between 25 and 300 m.

Figure Media motion in the tumbling mill. Grinding Grinding action Industrial grinding machines used in the mineral processing industries are mostly of the tumbling mill type. These mills exist in a variety of types rod, ball, pebble autogenous and semiautogenous. The grinding

UNTIL THE THIRD THEORY OF COMMINUTION of "Work Index" method of determining crushing and grinding mill size was introduced, there was no way of accurately figuring the most applicable, most economical size of crushing and grinding mill. Naturally, with little or no factual operating data correlated in useful form, it was easy enough, even for the most experienced, to arrive at an incorrect ...

Every mining operation has a unique grinding process. has experience of over 8,000 grinding mills globally, including manufacturing and delivering the largest SAG/AG mills in the world. Our experts welcome the opportunity to assist you with circuit and circuit control design as well as startup, operation, and optimization of your mill.

Mar 29, 2013· Hammer Mill Application Focus: Grinding Grains for Animal Feed. Posted March 29, 2013 by Schutte Buffalo. Producers of animal feed all know a simple truth: when processing cereal grains for animal feed, finished particle size matters.

Jul 25, 2011· Union Process is the source for the most uptodate information on grinding balls and other media. This video explains the 11 factors to consider in selecting the right grinding .

Figure Media motion in the tumbling mill. Grinding Grinding action Industrial grinding machines used in the mineral processing industries are mostly of the tumbling mill type. These mills exist in a variety of types rod, ball, pebble autogenous and semiautogenous. The grinding

How To Size Grinding Mill. ... Mill grinding Wikipedia A mill is a device that breaks solid materials into smaller pieces by grinding crushing or cutting Such comminution is an important unit operation in many processesThere are many different types of mills and many types of materials processed in them.

Oct 10, 2019· How to Achieve Consistent Particle Size and Dispersion with Your Mill or Grinder. Many products depend on the consistent pulverizing, micronizing, or particle size reduction of raw materials, followed by their uniform dispersion into the product matrix. By Angelo DePalma, PhD | October 10, 2019.

A comparison of the size reduction by impact and ball mill grinding is shown in figure 2. The ball mill experiments show the size reduction versus energy input for 7 series of experiments in which the weight of dolomite was 660, 1320, 1980, 2640, 3300, 3960, and 5420, respectively.

In this article, alternative forms of optimizing the milling efficiency of a laboratory scale ball mill by varying the grinding media size distribution and the feed material particle size distribution were investigated. Silica ore was used as the test material. The experimental parameters that were kept constant in this investigation was the ...

mill equipment size, but also dictates how to operate the mill, whether continuous or batch operation is required, and whether the process can be performed inhouse or if a tolling service is a better option. The required product size is an important grinding cost factor, especially for finesize grinding.

Clean the mill and grinding mechanisms with a small dry brush. Wipe the body of the mill with rubbing alcohol. Air dry all parts for at least 24 hours. Add dry rock or sea salt to the salt mill. Include a few grains of rice to absorb any moisture. Lubricate the threaded part of the mill.

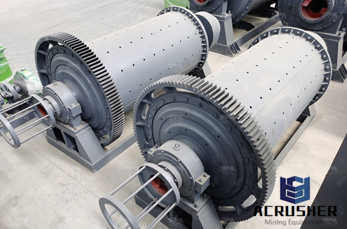

Grinding mills are specially developed for a vast range of applications including: size reduction of material, wet or dry grinding, and continuous or batch operations. Crushers are used to reduce particle size enough so that the material can be processed into finer particles in a grinder. A typical processing line at a mine might consist of a ...

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

HCH1395 is the biggest ultra fine circleroll grinding mill in China. This HCH ultrafine grinding mill features in spacesaving, completeness, wide use, easy operation, smooth performance, high performancecost ratio and high efficiency. HCH Ultrafine Grinding Mill (Live Video)

Oct 08, 2018· If you liked this video please give like and subscribe. Stay tuned for more videos from this channel. Thank you for watching .

Aug 25, 2011· SWECO VibroEnergy Grinding Mills are the most versatile line of mills available today for fast, lowcost particle size reduction to submicron range. VibroEnergy grinding action achieves higher ...

Optimization of Cement Grinding Operation in Ball Mills Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with...

WhatsApp)

WhatsApp)