CAM MOP30 Ball Mill CAM srl

CAM MOP30 Ball Mill The CAM MOP30 is a ball mill with a production capacity of Kg (±6%) of lead oxide (PbO) in 24 hours, with an oxidation of 72% (±3 points) and an acid absorption between (230÷260) mg H2SO4/g PbO.

WhatsApp)

WhatsApp)

CAM MOP30 Ball Mill The CAM MOP30 is a ball mill with a production capacity of Kg (±6%) of lead oxide (PbO) in 24 hours, with an oxidation of 72% (±3 points) and an acid absorption between (230÷260) mg H2SO4/g PbO.

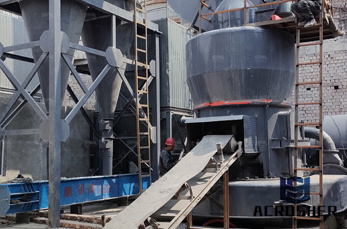

CHAINLESS LEAD OXIDE MILL Based on Sovema''s longterm experience in the supply of lead oxide production systems, this innovative piece of equipment features compact design with high performance. The ball mill is available in three versions with different capacities: up to 30 t/day, 24 t/day, and 14 t/day. MILLMASTER CONTROL SYSTEM

Grey Oxide is used on an extensive scale for preparation of plates in Lead Acid Batteries which requires production to strict specifications .Refined Lead (% purity) ingots are the required input for our LSO manufacturing plant, which uses the ball mill process. It comprises of a small Lead Melting Furnace, operating in line with a ...

Lead oxide, which is used to create the paste used on the battery plates, is either produced by the Ball Mill Process or the BartonLike may also be purchased from an oxide producer (see receiving). The major source of lead exposure in the oxide production process comes from leaking equipment and system upsets.

China Lead Acid Battery Assembly Machine supplier, Lead Acid Battery Assembly Line, Lead Oxide Ball Mill Manufacturers/ Suppliers Tai′an Shuanglong Storage Battery Equipments Co., Ltd.

Lead oxide ball mill system has a molten lead in the Melting Pot and it is pumped onto cylinder casting machine at a rate higher than that of oxidation pro.

Grey Oxide produced in Ball Mill Plant, which comprises of a small Lead Melting Furnace, operating in line with a hemispherical / cylindrical ballcasting machine, which feeds the balls to the ball mill. In the ball mill, Lead is converted to Lead Sub Oxide, which is an exothermic process.

The Ball Mill is suitable to produce lead oxide by means of friction between the cylinders produced before by the cylinder casting machine (Shimadzu method).Six parts compose it: – Rotating room. It is made of steel, welded on the generatrix and mechanically worked, in order to enable the assembling using hubs, on which the ball bearings are assembled.

Lead Oxide And Zirconia Ball Mill Cryogenic Grinding Mill Media With Direct Factory Prices, Find Complete Details about Lead Oxide And Zirconia Ball Mill Cryogenic Grinding Mill Media With Direct Factory Prices,Zirconia Ball Mill Grinding Media,Cryogenic Grinding Mill,Lead Oxide Ball Mill from Mine Mill Supplier or ManufacturerHenan Bailing Machinery Co., Ltd.

Manufacturer of Lead Oxide Plants Ball Mill Oxide, Red Lead Furnace, Hammer Mill and Barton Oxide Plant offered by Punjab Chemlead Pvt. Ltd., Jalandhar, Punjab.

Ball Mills. Eagle Ball Mill Oxide Systems Quality Oxide From the Oxide Equipment Experts! Battery performance is dependent upon the quality of lead oxide used. This is why Eagle''s ball mill systems have been designed to produce high quality battery oxide for a wide range of battery types.

Mini Grinding Plant 200 Mesh Lead Oxide Ball Mill, Find Complete Details about Mini Grinding Plant 200 Mesh Lead Oxide Ball Mill,Lead Oxide Ball Mill,Ball Mill,Mini Ball Mill from Mine Mill Supplier or ManufacturerZhengzhou General Mining Machinery Co., Ltd.

BACKGROUND REPORT AP42 SECTION LEAD OXIDE AND PIGMENT PRODUCTION Prepared for ... Low temperature oxidation of lead is accomplished by tumbling slugs of metallic lead in a ball mill equipped with an air flow. The air flow provides oxygen and is used as a coolant. ... LEAD OXIDE AND PIGMENT PRODUCTION EMISSION FACTORS All Emission Factors ...

lead oxide ball mill manufacturer/supplier, China lead oxide ball mill manufacturer factory list, find qualified Chinese lead oxide ball mill manufacturers, suppliers, factories, exporters wholesalers quickly on

Union Process is the source for the most uptodate information on grinding balls and other media. Click the link above to view a detailed sheet, outlining factors to consider when selecting grinding media, along with specifications on the most common types of media.

Another oxide production method involved the adaptation of a ball mill (commonly used for wet or dry grinding of ores, pigments, and other materials by the action with iron balls into a large rotating chamber) by using lead balls tumbling against one another.

AP42, CH 1216: Lead Oxide And Pigment Production. 1216 Lead Oxide And Pigment Production Low temperature oxidation of lead is acplished by tumbling slugs of metallic lead in a ball mill equipped with an air flow The air flow provides oxygen and is used as a coolant If some form The lead oxide emission factors from the battery plants. View More ...

The production rate of a ball mill process is indicated in the manufacturer''s technical specifications and it is proportional to the drum rotation speed. The energy needed for the production of 1 ton of lead oxide is fairly constant when the mill operates at between 55% and 90% of its critical rotation speed.

Lead oxide ball mill is a key machine mainly used to process lead oxide In grinding system, Beside that it is widely used in various manufacture industries, like cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics. Besides, it can also used in dry and wet grinding for all kinds of ores and other grindable materials.

CAM MOP 14 Ball Mill The CAM MOP14 is a ball mill with a production capacity of Kg (±6%) of lead oxide (PbO) in 24 hours, with an oxidation of 72% (±3 points) and an acid absorption between (230÷260) mg H2SO4/gr PbO.

Lead Oxide And Pigment Production General12,7 Lead oxide is a general term and can be either lead monoxide or "litharge" (PbO); lead ... of the tumbling charge would raise the charge temperature above the melting point of lead. The ball mill product is a "leady" oxide with 20 to 50 percent free lead.

Ball Mill Eagle Oxide Services. production rate of oxidation process. As the lead cylinders are tumbled inside of the ball mill, they oxidize on their surface to lead oxide.

Machinery has many kinds of ball mill for sale, such as small ball mill, lead oxide ball mill, industrial ball mill, etc. In addition, the ball mill prices of our company are preferential. Welcome to make an enquiry! Ball Mill Technical Data

Grey Oxide is used on an extensive scale for preparation of plates in Lead Acid Batteries which requires production to strict specifications .Refined Lead (% purity) ingots are the required input for our LSO manufacturing plant, which uses the ball mill process.

WhatsApp)

WhatsApp)