Coefficient of Friction Equation and Table Chart ...

Material: Against Material: Static Coefficient of Friction: Dry Contact: Lubricated Contact: Aluminum. Aluminum: : AluminumBronze Alloy :

WhatsApp)

WhatsApp)

Material: Against Material: Static Coefficient of Friction: Dry Contact: Lubricated Contact: Aluminum. Aluminum: : AluminumBronze Alloy :

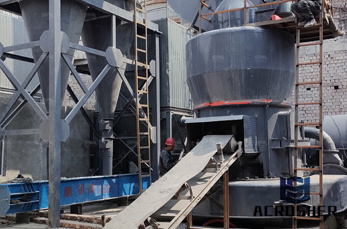

Crusher tooth material with Babbitt abrasion resistance alloy (hardness HRC45~55, impact toughness AK≥38kg•m/cm2 ),with strong impact resistance and wear resistance, the service life is 23 times longer than that of high manganese steel or common wear resistant alloy.

TinBased Babbitt Issue Date ... Nickel is suspected of causing cancer. Causes damage to organs through prolonged or repeated exposure (respiratory system, skin). 3 ... (HEPA) filtered vacuum equipment or by wet cleaning. ...

Babbitt metal or bearing metal, is any of several alloys used for the bearing surface in a plain bearing.. The original Babbitt alloy was invented in 1839 by Isaac Babbitt in Taunton, Massachusetts, United disclosed one of his alloy recipes but kept others as trade secrets. Other formulations were developed later. Like other terms whose eponymous origin is long since deemphasized ...

This is a tin based babbitt with the addition of a small amount of nickel. According to literature on this product, it is very similar to a ASTM B23 Grade 2 Babbitt with the addition of Nickel. Belmont Metals¶ Belmont Metals, Inc. was founded by George Henning in 1896 as a non ferrous scrap dealership on Brooklyn''s Belmont Avenue. The ...

DuraKapp™#4X Nickel Babbitt adds Nickel to the #2 Babbitt matrix to increase tensile and compression strength in high temperature bearings. Kapp Alloy uses special high grade raw materials and our proprietary Precision Microcasting™ process to produce the most consistent superior strength Babbitt available.

Feb 03, 2020· Melt the Babbitt metal. Use the cast iron lead melting pot. Heat the Babbitt metal to the desired pouring temperature depending on the Babbitt alloy. An electric lead pot designed to cast bullets is the preferred method because the pot has a temperature control. The melters typically are available at armory supply shops and specialty forging shops.

XXXX Nickel Babbitt is the result of over sixty years constant effort to produce the best bearing alloy, regardless of cost. Today it stands supreme in the field of highgrade bearing metals. It is made only of carefully selected materials and each element is subjected to .

Babbitt is used as a bearing material in equipment subject to significant heat, pressure, shock load and speed. They often operate in dusty, dirty, wet, and corrosive environments. The failure of a Babbitt bearing requires expensive repair and lengthy downtime. The proper application of Babbitt requires specialized highly skilled processes.

(HEPA) filtered vacuum equipment or by wet cleaning. Prevention of secondary hazards Clean contaminated objects and area thoroughly observing environmental regulations. 7. HANDLING AND STORAGE Precautions for safe handling Advice on safe handling Use personal protection recommended in Section 8. Avoid generation of dust.

General Materials (Powder, Ore, Solids, etc) kg/; Alfalfa, ground: 256: Alum, lumpy: 881: Alum, pulverized: 753: Alumina: 961: Aluminum, oxide: 1522: Ammonia gas

The mass of over 300 different ''dry'' materials are listed below. Liquids, metals and woods are on other pages and a site search facility is on the home data is useful for the design and selection of bulk materials handling plant, bulk transport and packaging, individual samples will differ.

Nov 22, 2010· Although the mix can vary considerably, Babbitt is an alloy of Tin and Antimony, commonly with Lead, and Copper, possibly with Nickel and Arsenic added according to the specific recipe. Despite what some metal producers catalogs say, real Bronze is an alloy of Copper and Tin.

Processing... ... ...

dekorasi balon, sumur resapan, telkom 1, telkom1,telkom, palapad, palapa d, palapa, balon, mkota, maanfaat sumur resapan, balon, siklus hidrologi

The Source of Engineering Subjects including Machine Design, Engineering Design, Mathematics, Mechanics and Strength of Materials, Mechanical Standards and Machine Elements

Brass, an alloy of zinc and copper, was known to the ancient Greeks and Egyptians. Pure zinc could not be isolated for a long time. In 1746, A. S. Marggraf developed a method for the production of metallic zinc that involved heating a mixture of zinc oxide and coal without air in clay refractory retorts, followed by condensation of the zinc vapor.

CuproNickel and Nickel Silver. The 7030 cupronickel alloys and the nickel silver alloys should have a sand with a permeability between 40 and 60 and a moisture content between and percent. The sand grain size should be about 95 Fineness Number, with an 18 percent clay content. Nickel silvers are sensitive to gas from organic binders.

08/04/2019 . PAPEL AISLANTE NOMEX #9 AL #20 Excelentes precios a Talleres y Empresas Contactarnos vía Whatsaap : Email: [email protected]

Babbitt of unknown composition. Magnolia Metal Corporation¶ Magnolia Metal Corporation began business in 1886 with a technical innovation in the then new bearing industry: the invention of leadbased babbitt metal. Less expensive than tinbased babbitt, "Magnolia AntiFriction" was soon being shipped around the world.

kaolin cosmetic clay powder in south africa BINQ Mining. extract the clay and shales Crushing and blending After being transported from the pit by truck or endless conveyor the materials are stockpiled to enable blending of the various types of clay The clays are fed separately by hopper or conveyor to the primary crushers in South Africa rolls or hammer mills are commonly used

This phase of grinding may be either the wet or dry process, the end product going to a kiln. Material ground consists of limestone, cement rock, marl or marine shells along with secondary materials usually shale or clay. A typical raw mix consists of 7585% limestone, 1225% shale, the balance consisting of silica or quartzite and iron oxide.

Nickel (CAS No) 030 Skin Sens. 1, H317 Carc. 2, H351 STOT RE 1, H372 Aquatic Acute 1, H400 Aquatic Chronic 3, H412 ... wet with water to cleanup dust. Use PPE described in Section 8. Vacuum must be fitted with HEPA filter to prevent release of particulates during cleanup.

XXXX Nickel Babbitt is recommended for use in: Blowers Dredges, Lumber Mills, Rock and Gravel Machinery, Cement Mills, Electrical machinery, Marine Service Steel Mills, Clay Working Machinery, Electric Railroads, Mining Machinery, Sugar Mills, Compressors, Engines, Internal Combustion Paper Mills Turbines, Crushers Engines Steam Pumps.

WhatsApp)

WhatsApp)