The Fast Guide to OEE Vorne

The Fast Guide to OEE™ Presented by Vorne Industries Specialists in Visual Factory and Production Monitoring Systems © Vorne Industries Inc., Itasca, IL USA +1 (630)

WhatsApp)

WhatsApp)

The Fast Guide to OEE™ Presented by Vorne Industries Specialists in Visual Factory and Production Monitoring Systems © Vorne Industries Inc., Itasca, IL USA +1 (630)

Performance Measurement of Mining Equipments by Utilizing OEE Sermin Elevli1 and Birol Elevli2 ... The next step after the estimation of OEE is to compare it with the benchmark values. Accepted benchmark value for the manufacturing industries is about 85% [17,18]. If the estimated OEE is below

Productivity and Cost Management . PwC ... mining industry Australia has some of the world''s largest coal reserves, but is ... •Benchmarking •Process Mapping •Resource Allocation Activity Solutions Discreet Activity Solutions Core Activities Exploration

Keywords:TPM, Availability, Performance, Utilization, Overall Equipment effectiveness (OEE). I. INTRODUCTION Mining involves very costly and highly automated equipment for extraction of minerals, the size of the equipment and capacity has increased many folds in the recent past resulting in poor utilization and inefficiency of the machines.

OpEx OEE (Operational Excellence Overall Equipment Effectiveness) is a Business Metric commonly used by the world''s leading Manufacturers to increase capacity, reduce costs and drive continuous improvement. OEE is a closedloop metric measuring the 3 critical manufacturing components of Availability, Performance and Quality.

oee definition benchmarking mining small scale mining equipment ... oee definition benchmarking mining. PE jaw crusher. PE series jaw crusher is usually used as primary crusher in quarry. Learn More; PEW jaw crusher. Workforce Management Consulting and Shift Work Strategy from Core Practice .

Performance Measurement of Mining Equipments by Utilizing OEE oee definition benchmarking mining,Acta Montanistica Slovaca Ročník 15 (2010), číslo 2, 95101 95 Performance Measurement of Mining Equipments by Utilizing OEE Sermin Elevli1 and Birol Elevli2what are the mineral types uses and location of mining in nigeriawhat are the mineral types uses and location of mining in nigeria ...

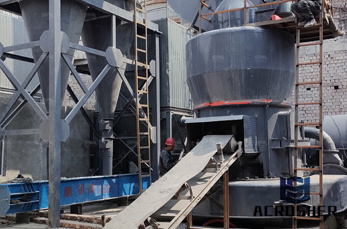

Oee Definition Benchmarking Mining. The relevant links of the mining crusher are as follows: Sodium Lauryl Provisions; ... Overall Equipment Effectiveness In Coal Mill Grinding Mill Defining a representative overall equipment effectiveness OEE effectiveness OEE measurement for underground bord and pillar coal mining OEE is defined as the.

Aug 02, 2013· A practical definition of OEE. OEE is the Overall Equipment Effectiveness of a defined production process during the defined operative period or mode in which all activities related to production, personnel and inputs are accounted for during all producing or dependent activities within a defined scheduled time or operative mode time.

Quick Definition. OEE is an abbreviation for the manufacturing metric Overall Equipment Effectiveness. OEE takes into account the various sub components of the manufacturing process – Availability, Performance and Quality. After the various factors are taken into account the result is expressed as a percentage.

This question gets asked a lot. Overall Equipment Effectiveness, also known as OEE, is typically viewed as a manufacturing improvement tool and as an indicator can contribute to the value of how well a factory or a factory line is we think of OEE in terms of mining it starts to get a little more complex, and you soon realize the standard manufacturing OEE doesn''t fit very well.

benchmarking the energy consumption of canadian underground bulk mines prepared for the mining association of canada and natural resources canada 1939a_oee.

Overall equipment effectiveness (OEE) is a measure of how well a manufacturing operation is utilized (facilities, time and material) compared to its full potential, during the periods when it is scheduled to run. it identifies the percentage of manufacturing time that is truly productive.

OEE is the single best metric for identifying losses, benchmarking progress, and improving the productivity of manufacturing equipment (, eliminating waste). This website is devoted to mastering the art and science of OEE. Understand it. Measure it. Improve it. Start here on your path to mastering OEE.

The Mining Association of Canada (MAC) has sponsored this energy benchmarking project. The focus is a detailed comparison of the energy consumption for openpit mining and concentration activities. The Office of Energy Efficiency of Natural Resources Canada (NRCan) has provided assistance for this study, which is a part of NRCan''s ongoing efforts

Oct 31, 2012· Overall Equipment Effectiveness: Benchmark Data by Industry Our goal is to benchmark over 1,000 companies by the end of the year so manufacturers will be able to compare their performance to their peers'' using metrics such as OEE, On Time and Complete Shipments, Successful New Product Introductions, and Cost of Quality.

5 definitions of OEE. Definition of OEE in Business Finance. What does OEE stand for? Printer friendly. Menu Search. New search features Acronym Blog Free tools ... What does OEE stand for? Your abbreviation search returned 14 meanings. showing only Business Finance definitions . Link/Page Citation Category Filters ...

Not all measurement should be timebased in mining. The Quality metric in OEE does exist in mining, and should not be set to . Production losses should NOT be stated in time! The overall Production of the measured asset should be directly related to the overall OEE % achieved.

Why the Preferred OEE Calculation? OEE scores provide a very valuable insight – an accurate picture of how effectively your manufacturing process is running. And, it makes it easy to track improvements in that process over time. What your OEE score doesn''t provide .

Again, the main difference between OEE, OOE and TEEP is the time or Availability that is used in each calculation. In other words, the only changing variable between these three calculations is the maximum time that you define as available for a machine to run. OEE, OOE, and TEEP all take availability, performance and quality into account.

Mar 29, 2019· OEE is a set of metrics that shows business leaders how much they are getting out of their production systems. If you need to calculate OEE for a company or business, or a single department or location, here are the common steps involved in figuring up this benchmark.

OEE (Overall Equipment Effectiveness) is a "best practices" metric that identifies the percentage of planned production time that is truly productive. An OEE score of represents perfect production: manufacturing only good parts, as fast as possible, with no downtime. OEE is useful as both a benchmark and a baseline:

"How to calculate Overall Equipment Effectiveness (OEE)" This is a primaryimportance topic in the Total Productive Maintenance (TPM) discipline. Before discussing about OEE, let me remind you of some basic principles of TPM. TPM was created originally by Nakajima over 20 years ago, and still considered today the leading Plant

Performance Measurement of Mining Equipments by Utilizing ... The next step after the estimation of OEE is to compare it with the benchmark values. Accepted .

WhatsApp)

WhatsApp)