Free Animation For Mining Mill

ball mill animation for mining plant ball mill animation for mining plant offers 231 kinetic sand products. About 13% of these are other toys hobbies, 11% are pet cleaning grooming .

WhatsApp)

WhatsApp)

ball mill animation for mining plant ball mill animation for mining plant offers 231 kinetic sand products. About 13% of these are other toys hobbies, 11% are pet cleaning grooming .

Acicular nodular iron rolls. Applications •Intermediate and Finishing stands of heavy and medium section mills. •Vertical rolls. Chemical composition C Mn Si Cr Mo Ni W, V Nb NIRA AC – .

3roll Reducing Sizing Block as finishing block for bar and/or prefinishing block for wire rod within the range of Ø mm – mm as well as corresponding hexagon dimensions 3roll RB 3roll Reducing Block applicable in roughing and intermediate mills of wire rod and bar mills to produce intermediate sizes within the range of Ø ...

world class rolls of the highest quality for over 100 years. The WHEMCO companies in Pennsylvania and Ohio, USA manufacture a full range of mill rolls – spun cast iron, cast steel and forged steel. Each of our roll manufacturing facilities has the expertise, equipment and experience to meet the most demanding rolling mill applications.

Section Mill We manufacture machinery for producing structure steel like Angle, Beam, Channels, Flat, and Girders etc. of various size range from 25 mm to 600 mm structure production capacity up .

Dec 10, 2015· Types of rolls used in various hot rolling mills. The types of rolls used in blooming and slabbing mill, billet and merchant bar mill, section mills, plate mill, and hot strip mill are given in .

Equipped with one of the best section and rail mill rolls brands, Kaida Roll Group is one of competitive universal mill roll, long products rolls, structural mill rolls, edger roll, edging mill roll manufacturers .

Section Rolls. Conventional Grades / Rolls / Heavy and Medium Section Mill. STEEL GRADES ALLOY CAST STEEL. Alloy Cast Steel rolls have a lower carbon content range than Steel Base qualities. .

Jun 18, 2014· Roll Pass Design. satyendra; June 18, 2014; 0 Comments ; Long products, roll grooves, Roll pass, Roll pass design, rolling mill, rolls, sections,; Roll Pass Design Long products are normally rolled in several passes, whose numbers are determined by the ratio of the initial input steel material (square or round billet or bloom) and final cross section .

Nov 17, 2012· The rolls do not touch the grinding ring even when the mill is empty. 16. of CE Bowl Mills 17. Mill Grinding rolls 18. 500 MW1. TYPE XRP OF MILL T/ – 525 600 RPM 19. 13.

rolls. 4 The gap between the rotating rolls is less than the thickness of the entering bar therefore a friction force is necessary in order to bite the bar and to pull it through the rolls. A metal bar passing through the rotating rolls is squeezed, and it elongates while its cross section area decreases. Forming Processes Rolling

Modern rolling practice can be attributed to the pioneering efforts of Henry Cort of Funtley Iron Mills, near Fareham, England. In 1783, a patent was issued to Henry Cort for his use of grooved rolls for rolling iron bars. With this new design, mills were able to produce 15 times more output per day than with a hammer. Although Cort was not the first to use grooved rolls.

A BOUT BENTEX. Bentex Industrials Pvt. Ltd. is a wellknown manufacturer and exporter of complete Steel Rolling Mill Machinery Shearing Machines, Pinion Gear Box, Pinion stands, Rolling mill stands and All types of Steel Rolling Mill Parts such as Bar Mills, Strip mills, Section mills, Pinch rolls, Wire Rod Manufacturers Producers, Reduction Gear Box,Rolling Mill Stands and Rotary shear etc.

A good roll design considers the dynamics of girth growth vs reduction and the subsequent edge distortion when determining the correct roll contour and fin angles. Reduction and Girth Control: The fin blade is a narrow roll .

• roll mill kenya ltd • city engineering works (k) ltd • gnanjivan screws fasterns ltd • impact industries (malaysia) • desbro international ltd • section rolling ltd • r. m. industries ltd • consolidated steel mills ltd • kamala rolling mills ltd • himal iron steel (p) ltd • kew metal works ltd

Section Rolling Mill. Rolling mills are facilities that carry out a series of processes including rolling the billets, blooms, slab and beam blanks – extracted from the reheating furnace – into the prescribed size and correcting any bending, cutting them into given lengths, .

Feb 25, 2016· The cross section area is reduced in each pass and form and the size of the stock gradually approach to the desired profile. ... If a mill rolls 800,000 tons per year using billets of .

A good roll design considers the dynamics of girth growth vs reduction and the subsequent edge distortion when determining the correct roll contour and fin angles. Reduction and Girth Control: The fin blade is a narrow roll segment that fits into the open gap at the top of the partially formed tube.

Section Rolls. Conventional Grades / Rolls / Heavy and Medium Section Mill. STEEL GRADES ALLOY CAST STEEL. Alloy Cast Steel rolls have a lower carbon content range than Steel Base qualities. The matrix can be heat treated to give either a spheroidised pearlite, which gives an alloy of maximum toughness, or a fine pearlite for additional wear ...

Equipped with one of the best section and rail mill rolls brands, Kaida Roll Group is one of competitive universal mill roll, long products rolls, structural mill rolls, edger roll, edging mill roll manufacturers and suppliers in China, welcome to visit our website.

Nov 09, 2016· The Endura® DualString Section Mill (DSSM) mills both inner and outer casing strings in plugandabandonment (PA) operations. By completely .

contribute to many of the roll neck failures that occur in 2HI mill work rolls or 4HI mill backup rolls. As a consequence, the market is demanding a rolling mills revamp to mitigate roll neck breakage in the .

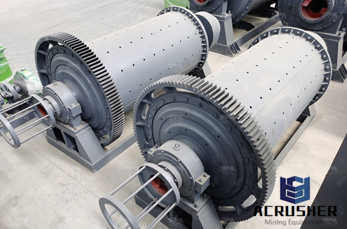

Rolls are tools used in rolling mills to reduce the cross section of metal stock. The weight of rolls may vary from a few kilograms up to 250 tonnes. Under rolling conditions the contact area between roll and stock suffers wear, the other parts of a roll body and necks have to be considered as normal parts of designed components under high ...

We provide a complete solution for Section Mill Rolls and we are manufacturer, exporter and supplier of various types of Section Mill Rolls which are used for various rolling application as most important component in Steel Rolling are manufacturer of rolling Mills rolls for various types of rolling Mills like Hot Rolling Mill Rolls, Steel Rolling Mill Rolls, Tube Mill Rolls, etc ...

WhatsApp)

WhatsApp)