Steel slag recycling plant(crushing plant) ATAIRAC ...

Crusher, Cone Crusher manufacturer / supplier in China, offering 2017 Good Price Granite Cone Crusher in Henan, Good Formance Ore Mineral Cone Crusher, Hot .

WhatsApp)

WhatsApp)

Crusher, Cone Crusher manufacturer / supplier in China, offering 2017 Good Price Granite Cone Crusher in Henan, Good Formance Ore Mineral Cone Crusher, Hot .

Roughly BOF slag, EAF slag and SMP slag can be defined as steel slags. Reviewing the past, utilization of ironmaking slag has a long history. The broken slag from ironmaking was already REUTER, M., XIAO, Y., and BOIN, U. Recycling and environmental issues of metallurgical slags and salt fluxes. VII International Conference on Molten

Solid Waste Management in a Steel Plant ... For example, until the last decade, the slag, dust and sludge generated by steel industry were called solid wastes, but now this term has been replaced by byproduct for these waste materials. ... These materials are either blended with iron ore fines or briquetted for recycling. Pellet plant.

Steel slag is the main waste product in the steelmaking process. Because of its chemical composition and technical properties, it can be reused as raw material in steel plants and can serve as a substitute for aggregates in civil engineering. In this paper, we reviewed steel slag treatment, recycling, and management in China.

Mechcon undertook a supply, fabricate and installation job for Multiserve One Steel at their steel Mill in Laverton. Works were for a newly built recycling plant, that was going to use leftover Granulated Slag which would be crushed down via the new conveyor plant, and then to be used for road base and other construction purposes.

Steel slag One of the main alternatives for recycling steel slag in Brazil has been its commercialisation as aggregate for railroad bed. Steel slag has also been used as road base and subbase. However, its expansive nature and the lack of reliable detection methods and criteria for acceptance have resulted in different durability problems.

Jun 04, 2018· This video is unavailable. Watch Queue Queue. Watch Queue Queue

Onsite slag recycling. Slag processing, or also referred to as bottom ash recycling or IBA recycling, and metal recovery on your site are the first steps in the range of services that Recco offers.. We engineer and manufacture a customized installation for temporary processing built up and installed from modular machinery or install a permanent system.

Slag from steel mills in ferrous smelting, on the other hand, is designed to minimize iron loss and so mainly contains oxides of calcium, silicon, magnesium, and aluminium. Any sandy component or quartz component of the original ore automatically carries through the smelting process as silicon dioxide.

Recycling iron and steel slag Steam aging facilities In fiscal 2011, our Kakogawa Works and Kobe Works together generated million metric tons of blast furnace slag and million metric tons of steel slag as byproducts.

We can establish any recycling plant in requested specifications and capacities. The plant capacity may vary between 60 tph to 1000 tph accroding to your requirements. Also we can revise any existing plant on turnkey basis. Our projects may include briquetting plants for benefitting small size metal slag in steel .

Figure 181 presents a diagram of the general flow and production of different slags in a modern steel plant. The steel slag produced during the primary stage of steel production is referred to as furnace slag or tap slag. This is the major source of steel slag aggregate. ... Recycling and Use of Waste Materials and ByProducts in Highway ...

Non ferrous recycling services We offer various services in non ferrous recycling to help you achieve the highest possible metal recovery profits. From building and exploiting an IBA processing plant on your site to non ferrous metal separation in our plant in Emmeloord. Also, our flexible arrangements allow a variety of cooperation.

Steel Slag Recovery Plant grinding mill equipmentiron recovery plant from slagmetalbeach iron recovery plant from slag 22/Jan/2018 Slag WikipediaWeb · Slag is the glasslike byproduct left over after a desired steel slag recovery for iron,Recovery Of Iron From Steel Furnace SlagSteel manufacture .

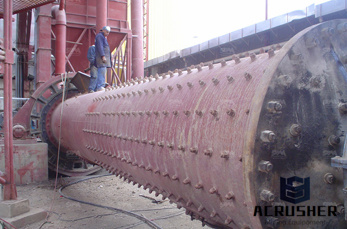

Slag utilization can produce huge economic and social benefits. Steel Slag Recycling Plant Structure . Steel Slag Recycling Plant is SBM response to the national energy saving policy, according to the hardness and other properties of slag through the rational allocation of equipment, and other resources for slag recycling production line.

RECYCLING OF LADLE FURNACE SLAGS Sima Aminorroaya1, Hossein Edris2, Ali Tohidi3, Jafar Parsi3, Bram Zamani3 Steel Research Institute Isfan Science and Technology Town, Dep. Isfan University of Technology, Steel Company Abstract Ferrous industry slag is waste product of all steelmaking manufactures.

More than 400 million tonnes of iron and steel slag is produced each year. Slags are a mixture of silica, calcium oxide, magnesium oxide, ... It is produced by recycling steel in an EAF. The main inputs are recycled steel and electricity. Depending on the plant ... provide up to 60% of the plant''s Alternatively, gases can be

Steel Slag – Material Description ORIGIN Steel slag, a byproduct of steel making, is produced during the separation of the molten steel from impurities in steel . Electric arc furnace – Steel plant, steel plant, steel plant .

Steel slag i ntroduction:. The steel slag crushing production line is a production line for recycling and recycling of steel slag and other resources based on the characteristics of steel slag hardness and rationally equipped provides customers with technical services and design of 30800tph steel slag processing line!

Characterisation of LD slag of Bokaro Steel Plant and its feasibility study of manufacturing commercial ''fly ash–LD slag'' bricks ... recycling and reuse of waste has become a necessary act ...

The special feature of LEGRAN''s metal slag processing system at the Lippe Plant is the way the material is treated. The slag and spent refractories need to be pulverised before they can be processed and this job is carried out by a rod and ball mill which dates back to the time when the site used to produce aluminium.

In November, 2015, chairman of Indonesia Growth Steel Group came to CHAENG and signed the EPC Turkey Project contract of 300,000 t/y nickel slag grinding plant. In May 2016, the vertical mill, auxiliary machine, and accessories of 300,000 t/y nickel slag grinding plant ordered by Indonesia Growth Steel Group were sent to Indonesia;

The current utilization rate of steel slag is only 22% in china, far behind the developed countries. At present, the amount of slag deposited in storage yard adds up to 30Mt, leading to the occupation of farm land and serious pollution to the environment.

We have over 20 years'' experience of processing Blast Furnace Slag and Steel Slag to make high quality aggregates. We process all such slag at Teesport and Scunthorpe Steel Works and consider ourselves to be the market leaders in this type of high quality aggregate recycling.

WhatsApp)

WhatsApp)