Cement Clinker | Definition of Cement Clinker by Merriam ...

Cement clinker definition is the glassy clinkerlike product of fusing together clay and limestone as the first stage in the manufacture of portland cement.

WhatsApp)

WhatsApp)

Cement clinker definition is the glassy clinkerlike product of fusing together clay and limestone as the first stage in the manufacture of portland cement.

Oct 23, 2011· The key difference between clinker and cement is that clinker appears as marblelike nodules, whereas cement is a very fine powder.. Earlier, people did not have sophisticated homes; therefore, they used simple things found in the environment to build houses. But today there are many advanced materials and equipment, which assist in constructions.

Process characteristics of clinker and cement production Johannes Ruppert CLUSTER Meeting, Hamburg, . Cement production and concrete as building material The properties of concrete make it a primary building .

Oct 06, 2019· Cement clinkers are formed by the heat processing of cement elements in a kiln. Limestone, clay, bauxite, and iron ore sand in specific proportions are heated in a rotating kiln at 2,770° Frenheit (1,400° Celsius) until they begin to form cinder lumps, which are also known as cement clinkers. These are usually ground with gypsum to produce the fine powder later mixed with liquid to .

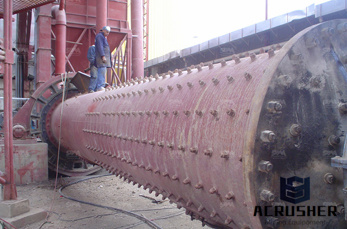

The clinker manufacturing process. The clinker manufacturing process starts with the extraction of the raw meal from the homogenization silo to insure that the raw meal is stable and homogenized in order to produce consistent clinker quality.

Cement Industry Overview. The gap between domestic production and consumption was filled in 2012 by over seven million metric tons of imported cement and cement clinker. Over 80 percent of cement and clinker imported in 2012 came from five major countries: China, Canada, Columbia, Mexico, and the Republic of Korea.

The gap between domestic production and consumption was filled in 2012 by over seven million metric tons of imported cement and cement clinker. Over 80 percent of cement and clinker imported in 2012 came from five major countries: China, Canada, Columbia, Mexico, and the Republic of Korea.

Cement Production: Focus on what really counts ... the need for optimized processes within the cement industry has never been higher. Think for example of the energy costs in the clinker manufacturing process, which can represent up to 75% of the variable costs. ... For effective process control in the clinker production process, optimized ...

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the '' Clinker '' pages.

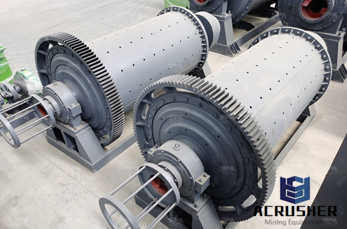

Then Clinker, gypsum and mixture is ground into qualified fineness cement in the cement mill. Classifier is adopted to adjust the fineness of cement, realizingenergy saving production. Cement packing machine and automatic loading machine are used for bagged cement delivery, and cement bulk device for cementcanning leaving factory.

In the European Union, the specific energy consumption for the production of cement clinker has been reduced by approximately 30% since the 1970s. This reduction in primary energy requirements is equivalent to approximately 11 million tonnes of coal per year .

CO2 Emissions from Cement Production 179 countries to collect clinker or cement production data from each plant in the country. To facilitate creating an uptodate inventory, countries should monitor imports and exports of clinker. Other important issues Baseline An emissions baseline is an important component of an inventory programme.

Jan 09, 2018· Cement is a mixture of compounds consisting mainly of silicates and aluminates of calcium formed out of silica, calcium oxide, aluminum oxide and iron oxide. We can state that cement is a hydraulic material made by finely grinding clinker (produce...

The cement industry is highly affected by regulatory norms. This is prominent in developed countries where environmental issues are more stringent. This adds to the companies'' costs. The blend is ...

4. Cement production. The clinker is processed into different types of cement. Apart from gypsum and clinker, various additives such as slag sand, trass and fly ash are also ground up with them, depending on the type of cement required. The MULTIDOS® weighfeeder feeds material into the mill, similar to the earlier feeding into the raw mill.

Nov 17, 2017· Clinker is the main raw material used for cement manufacturing. The lime stone powder, iron ore, alumina are all made into a powery form and the same will be preheated and this preheated material will be sent thro'' a rotary kiln and coal powder wi...

In the manufacture of Portland cement, clinker occurs as lumps or nodules, usually 3 millimetres ( in) to 25 millimetres ( in) in diameter, produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilicate materials such as clay during the cement kiln stage.

The Cement Production Process. Cement kilns are massive cylindrical structures, lined with refractory brick, into which a limebearing material and fuel such as coal or gas is fed. There is a range of different kiln designs but all rely on the same basic processes — raw feed passing through the kiln is heated to very high temperatures by the ...

Clinker Cement; 1: Clinker is a nodular material which is used as the binder in cement products. Cement is a binding agent that sets and hardens to adhere to building units such as stones, bricks, tiles etc. 2: Clinker is a granular substance containing spherical pellets of diameter 325 mm.

After the clinker is cooled, cement plants grind it and mix it with small amounts of gypsum and limestone. Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects.

Portland cement clinker overview. Portland cement clinker is a dark grey nodular material made by heating ground limestone and clay at a temperature of about 1400 °C 1500 °C. The nodules are ground up to a fine powder to produce cement, with a small amount of gypsum added to control the setting properties. This page gives a thumbnail sketch.

They are called cement rocks because they can be used as a single raw material for the cement manufacturing process. 3. Gypsum: It is generally added in very small amounts (about 2% by weight) to the burnt cement (called Clinker) after it is taken out from the kiln and before it is sent for grinding.

Clinker minerals react with water to produce the hydrates that are responsible for cement''s setting and strengthgiving properties. Reaction with water occurs only at the surface of the clinker particle, and so only proceeds rapidly if the clinker is finely ground to produce a large reaction surface.

Aug 30, 2012· Cement is the basic ingredient of construction and the most widely used construction material. It is a very critical ingredient, because only cement has the ability of enhancing viscosity of concrete which in returns provides the better locking of sand and gravels together in a concrete mix.

WhatsApp)

WhatsApp)