Work Rest / Gringing Jig |

Jan 29, 2013· When I made my first work rest for my grinder, my buddy, David suggested round versus square tubing. I had X,Y,Z control, but no angle control. That...

WhatsApp)

WhatsApp)

Jan 29, 2013· When I made my first work rest for my grinder, my buddy, David suggested round versus square tubing. I had X,Y,Z control, but no angle control. That...

This page describes the technology of centreless (centerless) grinding as well as centreless (centerless) grinding machines from Koyo Machine Industries. With centreless (centerless) grinders, a workpiece is supported by a work rest blade and set between a rubber regulating wheel that rotates the workpiece and a rotating grinding wheel.

Sep 10, 2014· HAUSER JIG GRINDING MACHINE TYPE S50L ... tompas11 352,991 views. 10:58. Work on Horizontal Boring machine Stanko 2L614 machining ... DeVlieg 43H72 Jig Bore Mill Centroid CNC retrofit ...

Explain the operation and working principle of a centre lathe with neat sketch. (16). 18. .. (i) Explain the working principle of centreless grinding machine.

If you have a jiggrinding problem, describe the details to us: Work piece material Work piece hardness Type of finish required Specific problem Our grinding wheel specialist will provide recommendations for wheel type, abrasive, grit size, speed and feed rate. Please contact the Moore Tool Abrasives Department. (203) or

Working Principles of jigging are pulsion suction. The effect of pulsion depends upon the laws of equalsettling particles, interstitial currents, and, possibly, also of acceleration. The chief function of pulsion is to save the larger grains of the heavier mineral, .

Working principle of jig boaring machine Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Working principle of jig boaring machine, quarry, aggregate, and .

Home Solutions principle and working of GRINDING MACHINE. principle and working of GRINDING MACHINE. Cylindrical grinder Wikipedia, the free encyclopedia The cylindrical grinder is a type of grinding machine used to shape the outside of an object. ... Course contents JIG GRINDING. Course contents:.

Design principles common to jig and fixture. 9:27 PM, Posted in Design Principles Common to Jigs and Fixtures. Design principles Common to jigs and fixtures: There are some principles which are useful to design jigs and fixtures. ... can be defined as " the incorporation of design feature in the jig or fixture that will make it possible to ...

Mar 09, 2017· When I started making knives the mechanical head in me told me to make a jig so bevels would be easy, it wasn''t if you didn''t know a lot of things about making knives, so now, many years later, here is my new knife grinding jig, I only have to make the front threaded holes for it to be finished, but my work week ended so, they are going to be ...

A grinding machine, often shortened to grinder, is one of power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting grain of abrasive on the wheel''s surface cuts a small chip from the workpiece via shear deformation.. Grinding is used to finish workpieces that must show high surface quality (, low surface roughness) and high ...

The fixtures are employed for handling work in milling, grinding, planing, or turning operations. Whereas the jigs are used for holding work and guiding the tool particularly in drilling, reaming or tapping operations. A plate jig is an improvement of the template jig by incorporating drill bushes on the template.

Grinding Services Business Directory, India Business Directory Job Work for Slide Way Grinding Machine....With portable in situ crankshaft grinding equipment our technicians come to your works or vessel to ..... Following the same principle, the mechanical motion of these shafts of the grinding .

May 25, 2013· a homemade tool, a lathe tool grinding jig not my design I found it on

How does a Jig Work. It is often hard for people to understand exactly how jigs work. For what it''s worth, I will put forth my understanding of the principles. Simply stated a jig is a device which has a couple of basic advantages over a sluice box. It is continuous and only needs occasional clean up (its biggest drawing card to hard rock mills).

Oneway also makes a jig for grinding skew chisels. Unfortunately, this jig doesn''t work well for skew chisels. Following Oneway''s directions, you achieve a curved hollow grind, which is wretched for architectural turners. The Sorby fingernail profiling jig is the most economical of the jigs.

Aug 12, 2009· My question is: Are there jigs for grinding out a blade to get it more uniform and repeatable? It would seem to me that if you were making a line of knives that you would want them all to be the same, and a jig would be a good way of going about that, but I have not been able to picture a jig that would accomplish this.

The WOLVERINE Grinding Jig is the CORE component of the ONEWAY WOLVERINE line of grinding products. Producing razor sharp tools and finely finished bevels has moved from an art into a science. Owning the WOLVERINE Grinding Jig will ultimately save you time, frustration and money. You can now grind your tools properly the first time.

Press Working Operations; Cutting And Forming Operations(Press Working) Press Working Operations; Press Working Operations; Grinding Fixtures; Lathe Fixtures or Turning Fixtures; Types of Fixtures; Design principles common to jig and fixture; Types of Drilling Jigs; Drilling Jigs; Elements of Jigs and Fixtures; Application of jigs and fixtures ...

Feb 16, 2016· Now that the Jig Grinder is all back together and functioning, Glenn and I take you on a tour of how to operate it. Stay tuned, there is much more to come.

Working principle. In centerless grinding, the workpiece is held between two wheels, rotating in the same direction at different speeds, and a workholding platform. One wheel, known as the grinding wheel (stationary wheel in the diagram), is on a fixed axis and rotates such that the force applied to the workpiece is directed downward, against the workholding platform.

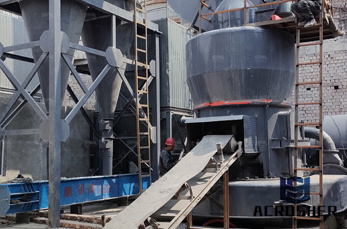

A Closer Look At Jig Grinding. Many technologies and methods used today in metal work are enhancements on older methods that may date back to a time of manual processing of parts and components. Jig grinding is one such method and process that is still highly beneficial for many parts. Using a jig grinder is the most effective way to grind ...

Sharpening and Grinding Jigs. ... ONEWAY HAS A SIMPLE FOUR STEP PROGRAM TO MAKE YOUR GRINDER WORK MORE EFFICIENTLY AND YOUR TOOLS LOOK AND BEHAVE THE WAY THEY SHOULD. STEP 1 WHEELS. Select wheels with the proper bond, grit and structure for your applications. The first secret to fast, efficient tool sharpening is choosing the correct wheels ...

Sep 27, 2019· A machine that can reshape metal and metallic items is often called a grinder. There are several types of these machines. A jig grinder is one that is often used to grind complex shapes and holes. It may be used to grind items such as jigs, dies, and gauges. Grinding machines generally work on a similar principle.

WhatsApp)

WhatsApp)